+86 15603181870

amy@chnhose.com

+86 15603181870

amy@chnhose.com

EPDM Liquid Cooling Hoses Selection Solution

2026-02-02

With the explosive growth of AI computing power and the soaring penetration rate of new energy vehicles, liquid cooling technology has transformed from an “optional” to a “must-have” in fields such as data centers, energy storage power stations, and new energy vehicles. As the “blood vessels” of the system, the selection of rubber liquid cooling hoses directly determines the stability, lifespan, and operation and maintenance costs of the entire cooling system.

With the explosive growth of AI computing power and the soaring penetration rate of new energy vehicles, liquid cooling technology has transformed from an “optional” to a “must-have” in fields such as data centers, energy storage power stations, and new energy vehicles. As the “blood vessels” of the system, the selection of rubber liquid cooling hoses directly determines the stability, lifespan, and operation and maintenance costs of the entire cooling system.

Depending on the operating conditions, liquid cooling hose materials are mainly divided into two categories: polymer materials and metal materials. To help you avoid selection pitfalls, we have compiled this selection scheme and installation guide for polymer EPDM liquid cooling hoses. Be sure to save it!

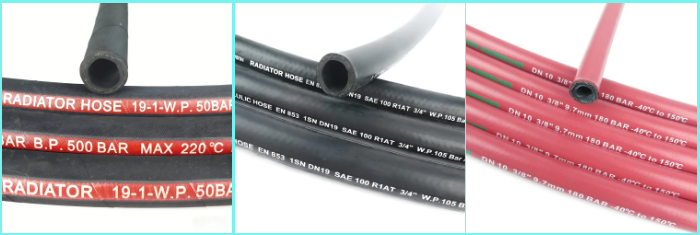

Textile Braid Liquid Cooling Hose

Made of EPDM material, with a temperature resistance range of -40℃ to 150℃, it is compatible with common coolants such as water-glycol and propylene glycol. It is cost-effective, highly flexible, and suitable for internal connections in server cold-plate liquid cooling systems. Note that a peroxide vulcanization formula must be selected to prevent sulfate leaching and coolant contamination. Combined with a polyester braided layer, it can withstand pressures of ≥0.6MPa, adapting to the 0.1~0.3MPa operating pressure requirements of servers.

Deep customization is available from color to appearance!

Wire Braid Liquid Cooling Hose

Selecting the right rubber liquid cooling hose is fundamental, but proper installation and precise sealing are crucial for ensuring the long-term stable operation of the system. Many leaks and pressure drops are not due to poor hose quality, but rather to improper installation and sealing procedures.

Pre-installation preparation: Three key checks to avoid inherent defects.

① The connector material must match the liquid cooling hose material and coolant medium: For example, EPDM or silicone seals and hoses are recommended for water-glycol coolant.

Low-pressure conditions (<1.0MPa): O-ring seals are used;

Medium-high pressure conditions (1.0~6.0MPa): Combined seals (O-ring + retaining ring) are used.

② The connector diameter and hose inner diameter must be precisely matched. Too loose a fit will easily lead to leakage, while too tight a fit will compress the hose and damage the inner wall.

① Wipe the cut surfaces and inner walls of the hose with ethanol to remove oil and dust, preventing impurities from entering the system and scratching the sealing surfaces or clogging the hoses.

② When cutting the hose, ensure the cut is smooth and burr-free, and the bevel angle does not exceed 5°. If the hose is bent or deformed, use a special tool to straighten it; do not forcibly straighten it.

For outdoor installations, allowance should be made in advance for thermal expansion and contraction (1%~2% of the hose length); In high-temperature conditions (>150℃), direct contact with heat sources should be avoided; in low-temperature conditions (<-40℃), it is forbidden to wrap a rigid insulation layer around the outside of the hose to prevent freezing and cracking.

Textile Cord / S&D Liquid Cooling Hose

On-site installation: 4 practical tips to avoid mechanical damage

Clamp-type connectors: Use stainless steel hose clamps.

Tighten until the clamp fits snugly against the hose without significant deformation.

Threaded connectors: When wrapping the PTFE tape, wrap it in the thread direction (avoid reverse wrapping to prevent blockage).

Refer to the connector specifications for tightening torque (M10 connector torque 8~10 N/m, M16 connector torque 15~18 N/m).

Piping should be kept away from sharp objects and high-temperature hoses; when running parallel to cables, maintain a distance of ≥5cm to prevent leakage and damage to the hose material.

A minimum of ≥20cm of maintenance space should be reserved at joint locations for easy disassembly and repair later.