+86 15603181870

amy@chnhose.com

+86 15603181870

amy@chnhose.com

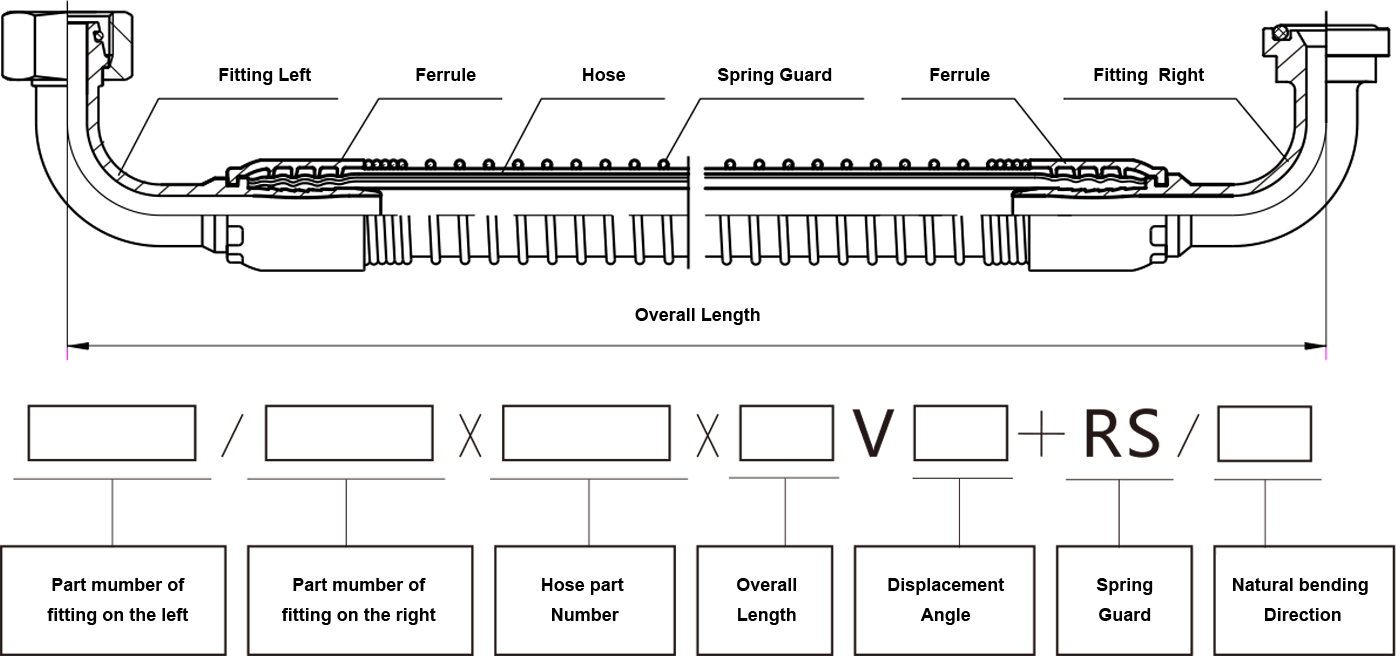

Ordering example 1: 20491-30-12T/S87391-12-12×2T12×1200V90+RS/SSX When there is no assembly angle, natural bending direction or spring sleeve, these contents can be omitted in the code. Ordering example 2: When the code of joint 1 is the same as that of joint 2, only one joint code needs to be marked. 20491-30-12T×2T12×1200V90

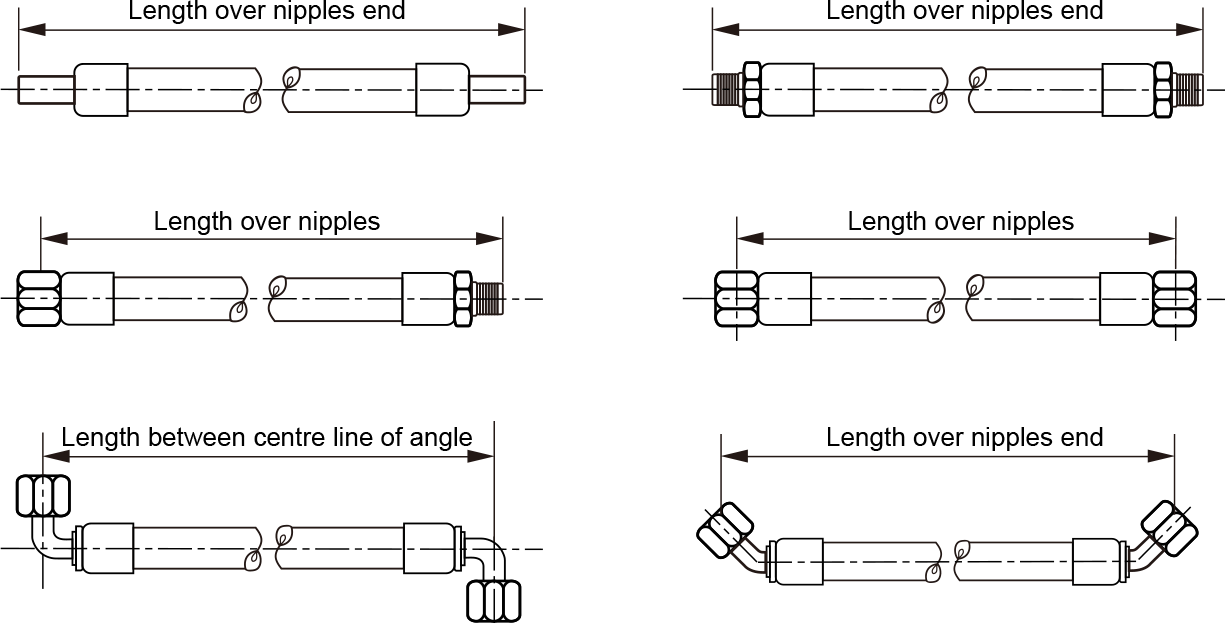

The total length L of the hose is measured based on the end face of the joint core or the center of the bent joint core

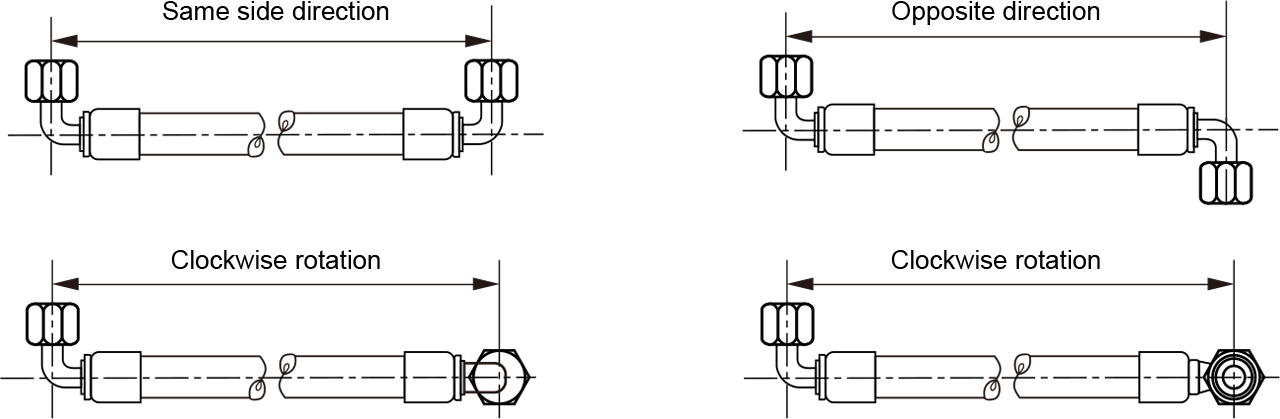

Place the rubber hose assembly on the same straight line, with one joint in the vertical direction: measure the angle between the other joint and the vertical joint in a clockwise direction. This included angle is the installation supporting role.

Assembly angle tolerance permit ±3°

When both ends of the assembly are bent joints, there is an angular relationship between the two bent joints during assembly. When measuring, straighten the hose assembly and look in the straight direction. Place the elbow 1 in the vertical upward direction. Measure the included angle between the elbow 2 and the vertically placed elbow 1 clockwise, that is, the assembly angle of the hose assembly, expressed in V. As shown in the figure, for example, when the assembly angle α is 225 °, the mark is V225.

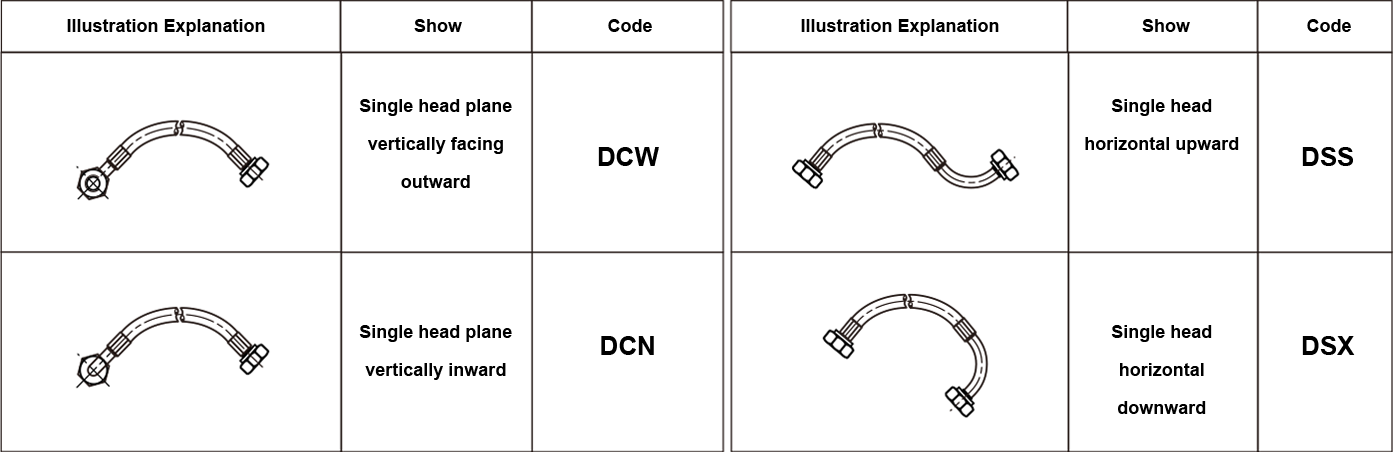

Due to the bundling and bundling of hoses in inventory, it is difficult to straighten them during assembly processing. When one end joint is a bent joint, there exists a relationship between the bent joint and the natural bending direction of the hose. Take the flat surface where the hose is naturally placed as the horizontal plane.

There are four situations when one end of the hose assembly is a bent joint and the other end is a direct joint:

There are ten situations when both ends of the hose assembly are bent joints: