In hydraulic technology, in addition to flow, pressure is undoubtedly the most relevant parameter and measurement value. In order to monitor, control, pre-maintain and maintain hydraulic equipment and systems, measuring system pressure is the most important and commonly used method. This is a prerequisite for the economical and effective operation of the equipment.

In the machine design stage, the test fitting has been designed and planned as a part of the equipment and installed in the appropriate position of the hydraulic system. The pressure test connector allows equipment operators and maintenance personnel to conveniently and safely connect analog computers and digital measurement and display equipment to temporarily or continuously test system pressure and other parameters. If necessary, the pressure tap can also be used to exhaust the system and collect fluid samples, for example, to analyze the degree of contamination of liquids. This type of connection does not require any tools, and can still be used normally at a system working pressure of up to 630bar in operation (the specific pressure depends on the type of pressure measuring connector selected).

The test fitting is generally connected to the pressure measuring hose. There is a corresponding thimble in the pressure measuring hose (there is also a dust cap with its own thimble). When the hose is connected, the thimble can open the self-sealing valve, and the fluid in the hydraulic system can flow out, and then sampling or pressure test can be performed.

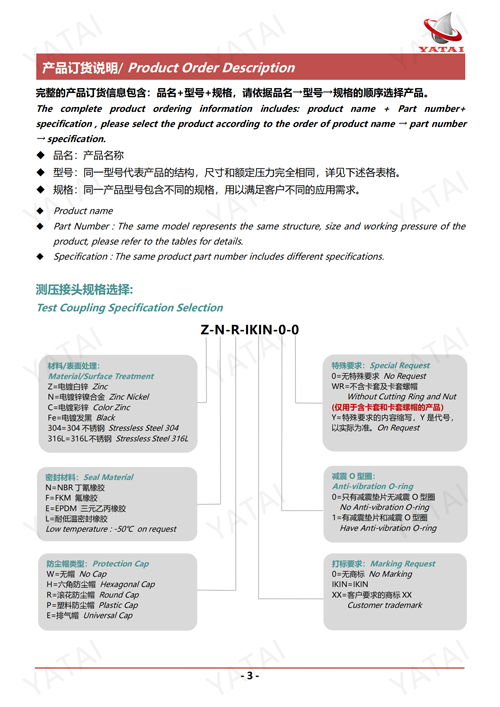

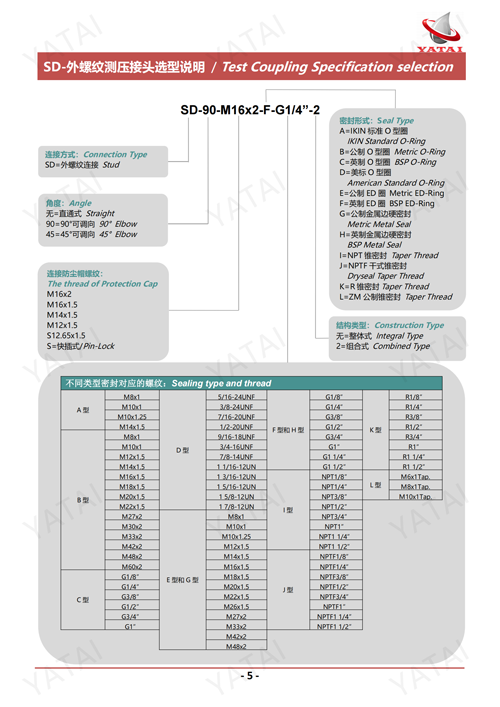

The selection categories are as follows:

Precautions:

If you use our test fitting instead of our test hose, the length of the needle cannot guarantee the opening and closing performance of the test fitting.If the needle is too short, the test fitting cannot be opened, resulting in no oil output; if the needle is too long, the test fitting will be over-opened, resulting in poor reset after opening and oil leakage of the test fitting . vice versa.

Therefore, our test hoses and test fittings should be used at the same time.

Contact US

Alice Kuang

mail :alice@chnhose.com

TEL: +86 15603187125