Hello, friends, welcome to Proleader & Yatai Industry zone!

The hose assembly is an important pressure hose component in the fluid industry, which performs many important functions. But in reality, a lot of people have some misunderstandings, and even some people think that a treasure to buy a joint, rent domestic buckle machine, workers training for half a day can be on the job. In fact, the production of hose assembly needs a wealth of theoretical knowledge, precise production equipment, professional staff, etc., Penny take you to know how to provide customers with high-quality hose assembly.

1. Rich theoretical knowledge

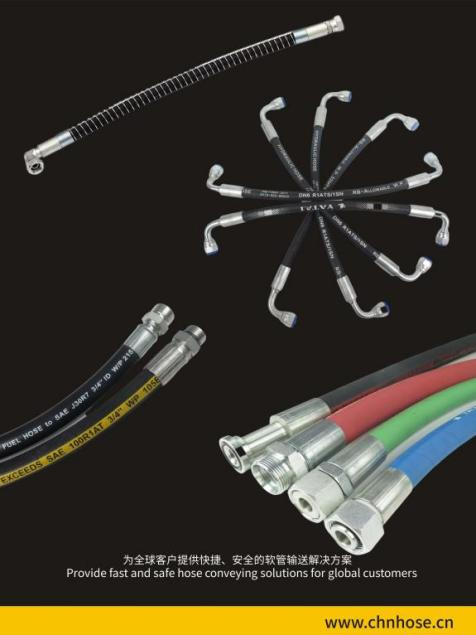

We all know that a hose assembly usually consists of three parts: hose, connector, and clamp or sleeve (push-on may not need clamp). The joint and sleeve are usually designed with Hose barb and other structures on the part in contact with the Hose, so as to achieve a good friction between the joint and the Hose and ensure that the joint withstands enough end force during use.

Assembly pressure value: we strictly in accordance with the relevant standards of the domestic and international rubber Association, combined with their own research and development of joint and sleeve, through technical professional calculation, accurate pressure value.

2. Sophisticated production equipment

As the saying goes: to do a good job, you must sharpen your tools. In modern industry, high quality products cannot be produced without sophisticated equipment. In recent years, PLD & Yatai pipe industry has introduced Finland finn-Power clamping machine, Germany UNIFLEX clamping machine professional equipment, its parameters are measured in millimeters, accurate to two decimal points, tolerance value is lower than the industry average level.

Test equipment: test bench can complete bursting test and assembly pressure test.

3. Professional skills of the staff

Two development and technical personnel, more than 50 product production team, fluid industry average working years of more than five years.

After reading these, I hope you start to have some interest in our products, and some more trust! Only with professional assembly manufacturers cooperation, in order to avoid worries. Welcome you to inquire, make an appointment to visit the factory!

Contact ways:

Technical consultation: Penny Chen

Tel:+86 18331807383( wechat synchronization)

QQ: 2673360390

Email: penny@chnhose.co